|

This article was first published in the West Sussex Gazette on November 23rd 1995.

In the 1930's, Surrey Wharf was still in use at Arundel. Coal for Bartlett's was unloaded from barges and stored in a large barn. Stables there housed the horses for the coal delivery carts.

These are more of 74 year old Ron Greenwood's memories of bygone Arundel.

'As you entered Surrey Wharf, on one corner was the blacksmith's shop, on the other a shop that sold fabrics and clothes. Then going down the right hand side was the rear entrance to the dairy next to the clothes shop. Then no.2 Surrey Wharf which was us, where we paid 5/- a week rent, followed by no.4 where the Clements family lived and then 'The Nook' where the Misses Bartlett lived before the entrance to the wharf.

'After the smithy on the other side was the large round wheel tyreing plate and the hearth on which was built the fire to heat the steel tyres for the cart wheels. This was right opposite our cottage. Wheel tyreing was done on average about once a month.

'Then came the brick-built shoeing shed for the horses and an alley-way for the back entrances to the properties in Tarrant Street. This was followed by a dirt road going off to the left along the back of Tarrant Street. There were some buildings along there, mostly as stores, and the road led to the premises of the brothers Mills who did most things with wood and were coffin makers and undertakers.

'As a lad, many a coffin did I watch being made often knowing the person it was for. Ralph Mills and his brother were very tolerant of nosy kids and I know how a good coffin should be made.

'In the 1920's there were two smiths working in the smithy, one was Tom Harding and the other, Charlie Southgate. Tom lived with his wife next door to the smithy and poor old Charlie lived over the river at the Brooks so he had the opposite walk to my grandfather each day. 'Then of course there were horses to shoe each day as well as making tyres for the farm carts and the general work of the blacksmith. Tom Harding retired in the late 1920s and, as mechanisation was rapidly replacing the horse, he himself was not replaced by another smith and Charlie Southgate carried on by himself.

'The smithy was owned by Abel Pierce and his two sons who had a wheelwrights' business just a short distance away down Surrey street. Here again, many things were made of wood, not least of course farm carts and horse carriages of different types.

'These men were truly craftsmen. There was practically nothing in the way of mechanical tools other than say a hand-turned drilling machine and a hand-operated mortising machine. It was 95% hand tooling in those days with a deftness of eye and hand that was near perfect.

'I would watch for hours the use of the spokeshave to make the wheel spokes and the simple wood-turning lathe for the hubs. The steel tyres were made in the blacksmith's shop.

'About once a month all the wheels, both new and used, awaiting tyres were tyred in one morning, always a Saturday, why I never knew.

'First, three large steel triangles were laid on the hearth in such a way that the largest tyre to be fitted when placed on them just touched each triangle at its base so you would have one at about 12 o'clock, one at 4 and one at 8 with their apexes pointing to the centre of the hearth. The tyres were laid on, one inside the other with the smallest in the middle.

Then four sheets of steel were stood top and bottom and each side. About six feet long and three feet high, they were pegged in place upright and the tyres were covered with shavings and waste wood from the wheelwrights shop and then fired. This was to heat and expand the metal slightly so that then the tyre was ever so slightly larger than the wheel it was for.

'Outside of the smith's house was a water tap from which many cans of water were filled in readiness. The largest wheel to be tyred was laid on the large round metal plate with its hub in the hole. When the fire was down and the smith judged it right the men from the wheelwright's shop were sent for to assist. The fire screens removed, the men using huge big pincers lifted the first and largest tyre from the ashes, carried it over to the wheel and offered it down to the edge of the wheel.

The wood of the wheel would char slightly, perhaps even burst into flame, while the smith ran around the men holding the tyre and knocked it onto the wheel with his forge hammer. The moment it was in place, water was poured on to it to shrink the metal to make an absolute tight fit. Later the smith would insert holding screws in holes pre-drilled in the tyre.'

Ron Greenwood visited the museum in Arundel in the 1980s and saw a number of tools and pieces of equipment from his grandfather's smithy and the wheelwright's shop, things Ron himself had used over sixty years ago to earn a little pocket money after school and on Saturdays.

In next week's Remember When read more about Ron's schooldays and his happy upbringing in the cathedral town of Arundel.

This article was first published in the West Sussex Gazette on November 23rd 1995.

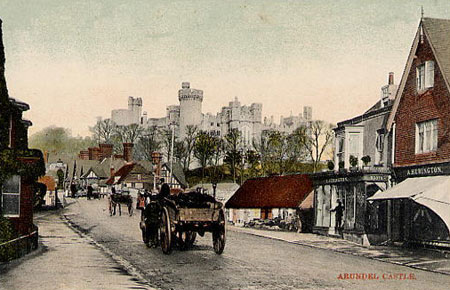

Coalman/horseman: Making coal deliveries by horse and cart in Queen Street, Arundel early this century. The shops on the right of the picture were occupied by A.Herington, drapers and outfitters, for more 100 years.

| |